Advanced adhesive applications, leveraging smart adhesives and high-performance polymers, revolutionize industries with improved structural integrity in automotive repairs, faster collision repair processes, and superior bond reliability. These innovations, grounded in material science principles of adhesion and cohesion, enhance efficiency, reduce downtime, and offer superior performance across sectors like manufacturing and restoration projects, from car scratch repair to aerospace components.

Advanced adhesive applications are revolutionizing industries, from manufacturing to healthcare. To truly unlock their potential, however, it’s crucial to understand the interplay of material science and innovative technologies. This article delves into the essentials of advanced adhesives, exploring how they work, their diverse industrial uses, and the transformative impact they’re having across various sectors. By understanding these fundamentals, we can appreciate the game-changing role of sticky solutions in today’s world.

- Unlocking Potential: Essential Technologies in Advanced Adhesives

- Material Science: Understanding Adhesion and Cohesion

- Industrial Applications: Transforming Industries with Sticky Solutions

Unlocking Potential: Essential Technologies in Advanced Adhesives

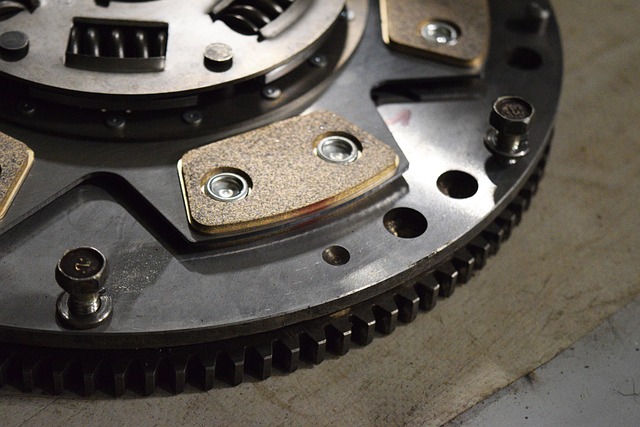

In the realm of advanced adhesive applications, unlocking new potential requires embracing cutting-edge technologies. These innovations are transforming industries, from automotive repairs to intricate manufacturing processes. One of the key drivers is the development of smart adhesives, which offer dynamic performance and adaptability, ensuring superior bonding in demanding environments. For instance, in auto maintenance and bumper repair, these advanced adhesives play a pivotal role in enhancing structural integrity while facilitating faster and more efficient car collision repair processes.

Additionally, advancements in materials science have led to the creation of high-performance polymers and resins, significantly improving adhesion strength and durability. These materials find applications in various sectors, ensuring enhanced bond reliability. Whether it’s for intricate assembly lines or specialized automotive restoration projects, these technologies enable precise and long-lasting connections. As a result, advanced adhesive applications revolutionize both industrial practices and everyday repairs, such as bumper repair, by offering improved efficiency, reduced downtime, and superior overall performance.

Material Science: Understanding Adhesion and Cohesion

In the realm of advanced adhesive applications, understanding the fundamental principles of material science is paramount. Adhesion and cohesion, key concepts in this field, refer to the forces that bind materials together. Cohesion describes the attraction between molecules within a single substance, enabling them to stick together. On the other hand, adhesion represents the force that binds one substance to another, allowing adhesives to create strong bonds between diverse materials.

This intricate interplay of adhesion and cohesion forms the backbone of effective advanced adhesive applications, including car damage repair and dent repair processes. In the context of car restoration, these principles ensure precise bonding during repairs, resulting in durable and seamless finishes. By delving into material science, professionals can optimize adhesive selection and application techniques, catering to a wide array of industries beyond automotive restoration.

Industrial Applications: Transforming Industries with Sticky Solutions

In various industrial sectors, advanced adhesive applications have revolutionized processes and product design, leading to enhanced performance, improved aesthetics, and streamlined manufacturing. These innovative solutions are no longer confined to household glue sticks; they encompass a vast array of specialized adhesives tailored for specific needs. For instance, in the automotive industry, advanced adhesives play a pivotal role in car scratch repair and auto collision centers, enabling precise restoration of vehicle bodywork to its original state.

From aerospace to electronics manufacturing, advanced adhesive applications have transformed sectors by offering superior bonding strength, weather resistance, and corrosion protection. In automotive assembly lines, for example, these adhesives secure components with precision, ensuring the structural integrity of vehicles while reducing weight and improving fuel efficiency. This shift towards lighter, more durable materials is a testament to the multifaceted benefits of advanced adhesive technologies in modern industrial landscapes.

Advanced adhesive applications have evolved far beyond their basic functions, thanks to innovative technologies and a deep understanding of material science. By leveraging advancements in polymer chemistry, surface treatments, and application techniques, industries across sectors are experiencing transformative changes. From improved structural integrity in manufacturing to enhanced bonding in medical devices, the potential of advanced adhesives is vast. As research continues to unveil new possibilities, these sticky solutions will undoubtedly play an increasingly crucial role in shaping the future of various industries.